Selecting the right lateral expansion joint for your industrial system is more than a purchase it’s a decision that impacts safety, efficiency, and long-term performance. Partnering with a reliable lateral expansion joint manufacturer ensures your pipelines and systems handle thermal shifts, vibrations, and pressure fluctuations without compromising integrity.

With countless options in the market, understanding key considerations helps engineers and procurement managers make informed choices. Let’s explore what truly matters when choosing a lateral expansion joint manufacturer, from material expertise to quality assurance and innovation.

Why Manufacturer Expertise Matters?

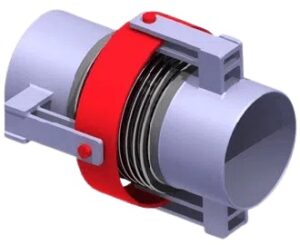

A manufacturer’s technical expertise often determines product reliability. Lateral expansion joints absorb lateral movement caused by thermal expansion, vibrations, or seismic activity. According to the American Society of Mechanical Engineers (.org), incorrect selection or installation can lead to costly system failures and maintenance downtime.

Key Points to Evaluate

- Experience: Look for manufacturers with years of industry presence and a track record of successful installations.

- Material Knowledge: Ensure they understand which metals, rubbers, or composites best suit specific industrial environments.

- Customization Capability: Every system is unique; the ability to design tailored solutions is crucial.

Quality Certifications and Standards

When it comes to lateral expansion joints, certifications are not optional—they’re essential. ISO certifications, ASME compliance, and rigorous testing protocols signal reliability. A trustworthy manufacturer will openly share product testing reports, fatigue analysis, and compliance documentation.

Beyond standard quality certifications, consider the manufacturer’s commitment to innovation. Advanced designs that mitigate stress concentrations or reduce vibration impact can dramatically increase service life, minimizing costly downtime.

Local Manufacturing vs. Global Sourcing

Choosing a lateral expansion joint in India can offer significant advantages. Local manufacturers provide faster lead times, easier communication, and post-installation support. They also understand regional industrial conditions, helping you select materials and designs optimized for your environment.

Additional Considerations

- Technical Support: Can the manufacturer assist with installation and troubleshooting?

- Maintenance Guidance: Do they provide clear instructions for routine inspection and upkeep?

- After-Sales Service: How responsive are they for warranty claims or replacement parts?

Some manufacturers also specialize in solutions for critical scenarios. For instance, Seismic Shock and Components that Protect from It offer systems designed to absorb extreme vibrations, protecting pipelines and reducing risk in earthquake-prone areas.

Evaluating Cost vs. Longevity

While initial costs matter, longevity and total lifecycle costs should weigh more. A cheaper expansion joint might save upfront expenses but could fail under thermal stress, leading to significant downtime and repair costs. Reliable manufacturers focus on durability and performance, ensuring your investment delivers returns over years of operation.

Checklist for Smart Purchasing

- Verify compliance with international standards and local regulations.

- Check customer testimonials and case studies.

- Request sample testing or site references when possible.

- Discuss customization and after-sales support options.

Frequently Asked Questions

1. What industries benefit most from lateral expansion joints?

Industries like power generation, oil & gas, chemical processing, and water treatment rely heavily on lateral expansion joints for system integrity.

2. How often should expansion joints be inspected?

Inspection frequency depends on usage, temperature variations, and pressure conditions, but a general recommendation is at least annually.

3. Can manufacturers provide custom designs?

Yes. Many reputable lateral expansion joint manufacturers offer tailored solutions to meet specific system requirements.

4. What materials are commonly used for lateral expansion joints?

Materials include stainless steel, rubber, PTFE, and composite blends, chosen based on temperature, pressure, and chemical exposure.

Final Thoughts

Selecting the right lateral expansion joint manufacturer is a strategic decision, not a routine purchase. By evaluating expertise, certifications, support services, and material options, industries can safeguard pipelines, reduce downtime, and optimize operational efficiency. Smart choices today prevent costly failures tomorrow.