For many industries, wastewater treatment quietly eats into profits every single day. Energy bills climb, chemicals get wasted, and maintenance feels endless. But here’s the twist—modern effluent treatment plants are no longer just compliance tools. When designed well, they actively reduce operating costs. In fact, companies that invest wisely often recover their costs faster than expected, sometimes without even realizing it at first.

Why Effluent Treatment Costs Add Up So Quickly?

Traditional effluent plants were built with one goal in mind: meet discharge norms. Cost efficiency came later—if at all. Older systems often rely on manual controls, energy-hungry motors, and chemical-heavy processes. Over time, this leads to:

- High power consumption due to inefficient aeration systems

- Excessive chemical dosing with little optimization

- Frequent breakdowns and unplanned shutdowns

This is where advanced systems and the best effluent plant providers begin to change the story. They approach wastewater treatment as a long-term operational asset, not a regulatory burden.

Automation: The Quiet Cost-Saver

One of the biggest cost reducers in advanced effluent plants is automation. Sensors, PLC controls, and real-time monitoring ensure the system runs only as hard as it needs to—nothing more.

How automation cuts expenses?

- Optimized energy use: Smart aeration adjusts oxygen levels automatically, cutting power consumption significantly.

- Lower chemical waste: Dosing systems respond to actual water quality instead of fixed assumptions.

- Reduced manpower: Less manual intervention means fewer operational errors.

According to the U.S. Environmental Protection Agency, energy-efficient upgrades in wastewater systems can reduce energy costs by 15–30% when implemented correctly (EPA.gov).

Water Reuse That Actually Pays Back

Advanced effluent plants don’t just treat water they recover it. Reuse-ready systems allow treated water to be used again for cooling towers, gardening, washing, or even process reuse after polishing.

Industries that reuse water effectively reduce their freshwater intake dramatically. The World Bank highlights that industrial water reuse can cut overall water costs by up to 40% in water-stressed regions (WorldBank.org).

This is where experienced effluent treatment plant manufacturers stand out they design plants with reuse economics in mind, not as an afterthought.

Lower Maintenance, Longer Equipment Life

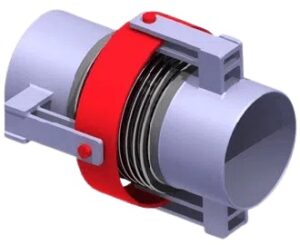

Advanced effluent plants are built using corrosion-resistant materials, modular designs, and smarter hydraulics. The result? Fewer breakdowns and longer service life.

- Modular components reduce downtime during repairs

- Predictive maintenance alerts prevent major failures

- Optimized flow paths reduce wear and tear

Over five to seven years, reduced maintenance alone can save lakhs sometimes crores for medium to large industrial facilities.

Compliance Without Costly Penalties

Non-compliance is expensive. Fines, production stoppages, and reputational damage often cost far more than system upgrades. Advanced plants are designed to consistently meet evolving discharge norms, reducing regulatory risk.

India’s Central Pollution Control Board continues to tighten effluent standards, especially for chemical, textile, and pharmaceutical industries (CPCB.gov.in). Staying ahead of these changes prevents sudden capital expenses later.

FAQs

1. Do advanced effluent plants really cost less in the long run?

Yes. While initial investment may be higher, savings from energy efficiency, water reuse, and lower maintenance often outweigh upfront costs within a few years.

2. Which industries benefit most from advanced effluent treatment?

Textiles, pharmaceuticals, chemicals, food processing, and manufacturing units with high water usage see the fastest cost recovery.

3. Can older effluent plants be upgraded?

In many cases, yes. Automation, energy-efficient aeration, and tertiary treatment modules can be retrofitted to existing systems.

4. Is water reuse safe for industrial operations?

When designed correctly and monitored properly, reused treated water is safe for multiple non-potable industrial applications.

Final Thoughts

Advanced effluent plants aren’t just about cleaner water—they’re about smarter operations. By cutting energy use, reducing water dependency, and minimizing maintenance headaches, they quietly improve the bottom line. In today’s cost-sensitive industrial environment, that kind of efficiency isn’t optional it’s strategic.