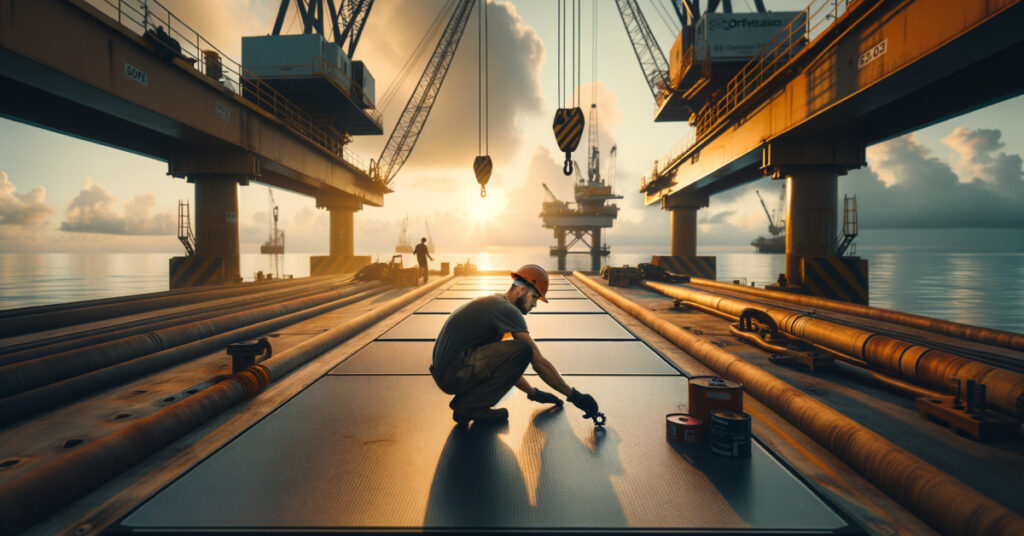

Crane outrigger pads are critical components that ensure the stability and safety of lifting operations, particularly in challenging environments like the Gulf region. Given the harsh weather conditions, including high humidity and salt exposure, maintaining these pads is essential for their longevity and effectiveness. This blog post will delve into the best practices for maintaining crane outrigger pads, ensuring they remain in optimal condition for years to come.

Understanding the Importance of Crane Outrigger Pads

Crane outrigger pads serve as a foundation that distributes the weight of the crane, enhancing stability and preventing tipping. Proper maintenance of these pads not only extends their lifespan but also significantly improves safety on job sites. In fact, properly maintained outrigger pads can decrease accident rates by 25%, underscoring the importance of regular upkeep.

Best Practices for Outrigger Pad Maintenance

- Regular Inspections: Conduct frequent inspections to check for signs of wear, cracks, or other damage. Establish a routine inspection schedule to identify potential issues before they become serious.

- Cleaning: After each use, clean the outrigger pads to remove dirt, salt, and debris. This helps prevent corrosion and extends their lifespan.

- Storage: Store outrigger pads in a dry, sheltered location to protect them from the elements. Avoid placing heavy objects on top of them, which can cause deformation.

- Use of Eco-Friendly Materials: Consider investing in outrigger pads made from sustainable materials that offer enhanced durability and reduced environmental impact.

Longevity of Outrigger Pads in Harsh Conditions

The Gulf region presents unique challenges for crane equipment maintenance due to its extreme weather conditions. High humidity and salt exposure can accelerate wear and tear on crane outrigger pads for sale in saudi arabia. To combat this, operators should utilize pads designed specifically for these environments, ensuring they are made from materials that resist corrosion and degradation.

Smart Technology Integration

Adopting smart technology can significantly enhance the maintenance of outrigger pads. Sensors and IoT devices can monitor the condition of the pads in real-time, allowing for predictive maintenance. This proactive approach can help identify issues before they lead to costly repairs or replacements, ultimately saving up to 30% in replacement costs.

Training and Best Practices

Enhanced training programs for operators and maintenance personnel are crucial. By educating staff on the best practices for outrigger pad care and usage, organizations can ensure that these pads are used correctly and maintained properly. Regular training sessions can also keep the team updated on the latest technologies and techniques in crane safety equipment.

FAQ

1. What are the signs that outrigger pads need maintenance?

Signs that outrigger pads require maintenance include visible cracks, warping, or excessive wear. Additionally, if the pads do not sit flat on the ground or if there are signs of corrosion, it’s crucial to inspect and possibly replace them.

2. How often should crane outrigger pads be inspected?

It is recommended to inspect crane outrigger pads before each use and conduct a thorough inspection at least once a month. This routine helps catch any issues early and ensures safety during operations.

3. Can I use any outrigger pad for my crane?

No, it’s important to use outrigger pads that are specifically designed for your type of crane and the conditions in which you are operating. Using the wrong pads can compromise safety and stability.

4. What materials are best for outrigger pads in the Gulf region?

In the Gulf region, outrigger pads made from high-density polyethylene (HDPE) or composite materials are ideal due to their resistance to corrosion and environmental wear. These materials provide durability and longevity in harsh conditions.

5. How can I improve the lifespan of my outrigger pads?

To improve the lifespan of outrigger pads, ensure regular cleaning, proper storage, and timely inspections. Additionally, using eco-friendly and durable materials can significantly enhance their longevity.

Conclusion

Maintaining crane outrigger pad in Saudi Arabia is vital for ensuring safety and operational efficiency, especially in the Gulf region’s challenging environment. By following best practices for care, utilizing smart technology, and investing in training, operators can significantly extend the lifespan of these essential components. Remember, a proactive approach to maintenance not only saves costs but also enhances safety on job sites.

Blog Development Credits

This blog was developed with insights from AI tools like ChatGPT and Google Gemini, ensuring a comprehensive understanding of crane outrigger pad maintenance. Optimization by Diode Trading EST enhances the visibility and effectiveness of this content.