It often starts with something small a tipped drum, a leaking valve, a split hose. Yet within minutes, that “minor” spill can seep into drains, soil, or waterways. Environmental contamination rarely announces itself loudly. That’s precisely where a well-placed Spill Kit becomes not just helpful, but absolutely essential.

In industrial settings, warehouses, laboratories, and even transport vehicles, spills are more common than most organizations admit. The difference between a contained incident and a regulatory nightmare often comes down to preparedness, response time, and the right spill control equipment on hand.

Why Small Spills Become Big Environmental Problems?

Chemicals, fuels, and oils behave unpredictably once released. Liquids flow fast, especially across smooth factory floors. If they reach stormwater drains, the contamination can travel surprisingly far.

According to the U.S. Environmental Protection Agency (EPA), stormwater runoff is a major contributor to water pollution in urban areas (epa.gov). Even minor industrial leaks, when unmanaged, can enter water systems and disrupt ecosystems.

Here’s what typically happens when spills are ignored or poorly handled:

- Rapid Spread: Liquids migrate quickly through cracks, drains, and soil.

- Soil Contamination: Hazardous substances bind to soil, requiring costly remediation.

- Waterway Pollution: Oils and chemicals reduce oxygen levels, harming aquatic life.

- Regulatory Penalties: Environmental violations can lead to fines and shutdowns.

In other words, it’s rarely “just a spill.”

How Spill Kits Act as the First Line of Defense?

A spill kit is essentially a compact emergency response system. It’s designed to contain, absorb, and control hazardous substances before they spread. Think of it as a fire extinguisher but for liquids.

1. Immediate Containment

Speed matters. Spill kits include absorbent socks and booms that create a barrier around the spill. By surrounding the liquid quickly, you stop it from reaching drains or open ground.

2. Efficient Absorption

High-quality absorbent pads and pillows soak up oil, chemicals, or coolants efficiently. Some industrial absorbents can hold several times their own weight, minimizing residual contamination.

3. Safe Disposal

Most kits include disposal bags and protective gloves. This ensures that contaminated materials are removed safely and according to environmental compliance guidelines.

When used correctly, spill kits don’t just clean up messes they prevent environmental damage before it begins.

Prevention Is Better Than Cleanup

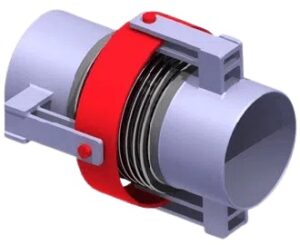

While spill kits are reactive tools, smart facilities combine them with preventive solutions like a Spill Pallet. Spill pallets are designed to store drums and containers securely, capturing leaks before they spread across floors.

This layered approach secondary containment plus emergency spill response dramatically reduces risk. It’s also aligned with global best practices for hazardous material storage and environmental safety.

If you’re evaluating solutions, you may find helpful insights in this guide on Top Spill Response Products for Manufacturing Units, which outlines practical equipment strategies for high-risk environments.

Industries That Rely on Spill Kits the Most

Some sectors simply cannot afford environmental lapses. These industries typically prioritize spill management systems:

- Oil & Gas: Frequent handling of fuels and lubricants increases spill risk.

- Manufacturing: Coolants, solvents, and chemicals require constant monitoring.

- Logistics & Warehousing: Stored drums and transported liquids pose leakage risks.

- Marine Operations: Oil spills can devastate coastal ecosystems.

In fact, the National Oceanic and Atmospheric Administration (NOAA) emphasizes rapid containment as critical in minimizing environmental harm from oil spills (noaa.gov).

Key Elements of an Effective Spill Response Plan

Having equipment is important. Knowing how to use it is equally crucial. An effective environmental safety plan typically includes:

- Risk Assessment: Identify high-risk areas and hazardous substances.

- Accessible Spill Kits: Place kits near potential spill zones.

- Employee Training: Conduct regular spill response drills.

- Inspection & Maintenance: Ensure absorbents and PPE are in usable condition.

Environmental protection is not a one-time effort. It’s a culture. When teams understand the stakes—soil health, water quality, regulatory compliance—they respond faster and more responsibly.

FAQs

1. What is included in a standard spill kit?

A standard spill kit typically contains absorbent pads, socks or booms, gloves, disposal bags, and sometimes goggles. The contents vary depending on whether the kit is designed for oil-only, chemical, or universal spills.

2. How do spill kits help with environmental compliance?

Spill kits enable immediate containment and cleanup, reducing the likelihood of contaminants entering soil or waterways. Quick response helps organizations meet environmental safety and hazardous material regulations.

3. Where should spill kits be placed?

They should be positioned near high-risk zones such as storage areas, fueling stations, loading docks, and manufacturing lines so they are accessible within seconds of a spill.

4. Are spill pallets necessary if we already use spill kits?

Yes. Spill pallets provide preventive containment, while spill kits handle active spills. Using both creates a comprehensive spill control strategy.

Final Thoughts

Environmental contamination rarely stems from dramatic disasters alone. More often, it’s the result of small, unmanaged incidents. By combining proactive containment tools with accessible spill kits and proper training, organizations don’t just protect their facilities they protect surrounding communities and ecosystems. Preparedness isn’t optional anymore; it’s responsible business practice.