In the world of engines, turbines, and heavy-duty machinery, small components often carry big responsibility. Exhaust expansion joints are one such part. For many Indian OEMs, the decision to work with a local exhaust expansion joints manufacturer India isn’t just about convenience it’s about reliability, speed, and engineering confidence built over years of collaboration.

Local Understanding Meets Real-World Conditions

India’s industrial environment is uniquely demanding. High temperatures, variable fuel quality, long operating hours, and space-constrained installations are everyday realities. Local manufacturers understand these challenges instinctively. They design exhaust expansion joints that don’t just look good on paper but survive on factory floors, power plants, and engine rooms.

OEM engineers often note that imported components are designed for ideal conditions, while Indian-made solutions are built for real ones. That difference matters when uptime is critical.

Faster Customization and Engineering Support

OEM projects rarely fit a standard template. Changes in layout, load conditions, or thermal movement often happen mid-project. Working with local manufacturers makes these adjustments smoother and faster.

Why OEMs Value Local Engineering Teams?

- Quick Design Iterations: Faster drawings, approvals, and prototypes.

- Direct Communication: Engineers speak the same technical and operational language.

- On-Site Support: Easier inspections, measurements, and troubleshooting.

This hands-on collaboration becomes especially important in complex systems involving vibration control and multi-directional movement topics explored in detail in How to Manage Complex Movements in Heavy-duty Applications?.

Supply Chain Reliability and Faster Lead Times

Global supply chains can be unpredictable. Shipping delays, customs clearance, and currency fluctuations add uncertainty to OEM timelines. Local manufacturers remove many of these variables.

According to insights shared by the Make in India initiative, domestic manufacturing significantly reduces procurement lead times and improves production continuity. For OEMs working on tight delivery schedules, this reliability often outweighs marginal cost differences.

Quality Standards That Match Global Expectations

There’s a common misconception that local manufacturing means compromised quality. In reality, many Indian manufacturers today follow international standards such as ASME, EJMA guidelines, and ISO-certified quality systems.

What OEMs Look for in Indian Manufacturers?

- Consistent material traceability and testing

- Proven welding and forming expertise

- Documented performance under high temperature and pressure

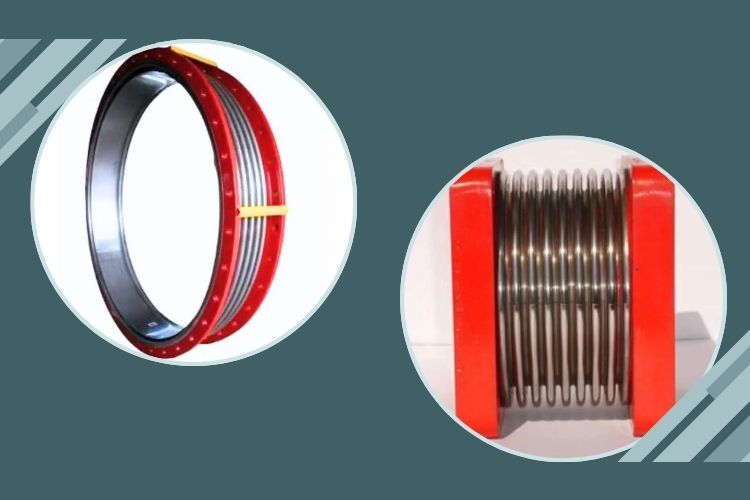

Midway through many OEM exhaust systems, components like bellows become critical. This is where partnering with a reliable exhaust pipe bellows expansion joints manufacturer makes a measurable difference in system longevity.

Cost Efficiency Without Cutting Corners

Cost matters but not at the expense of performance. Local manufacturers strike a balance by reducing logistics, import duties, and extended lead times while maintaining material and fabrication quality.

OEMs also benefit from lifecycle savings. When replacement parts, inspections, or upgrades are needed, local suppliers respond faster, reducing downtime and maintenance costs.

Alignment with “Make in India” and ESG Goals

Many OEMs today are under pressure to localize sourcing and reduce carbon footprints. Partnering with Indian manufacturers supports domestic industry while lowering emissions associated with long-distance shipping.

As noted by International Energy Agency studies on industrial efficiency, localized supply chains can contribute to more sustainable manufacturing practices an increasingly important factor in OEM decision-making.

FAQs: Indian OEMs and Exhaust Expansion Joints

1. Why do OEMs prefer Indian manufacturers over imports?

Indian manufacturers offer faster lead times, easier customization, and better understanding of local operating conditions.

2. Are Indian exhaust expansion joints globally competitive?

Yes. Many Indian manufacturers meet international standards and supply to global OEMs.

3. Do local manufacturers support custom designs?

Absolutely. Customization and engineering collaboration are key strengths of Indian suppliers.

4. How does local sourcing reduce overall costs?

It minimizes logistics expenses, import duties, delays, and long-term maintenance downtime.

Final Thoughts

For Indian OEMs, choosing local exhaust expansion joint manufacturers is a strategic decision not a compromise. It’s about speed, trust, adaptability, and long-term performance. As Indian manufacturing continues to mature, these partnerships are only getting stronger, smarter, and more globally competitive.