In large industrial plants, pipelines quietly do the hardest work—carrying heat, pressure, and critical fluids day after day. But what happens when these pipes expand, shift, or vibrate? Designing flexible systems is no longer optional. For Indian engineers, choosing the right expansion solution has become a practical necessity, not just a design preference.

Whether you are working in a refinery, power station, or chemical unit, partnering with a reliable gimbal expansion bellows manufacturer early in the design stage can save months of troubleshooting later. It is often the difference between a system that ages gracefully and one that constantly demands repairs.

Understanding Gimbal Expansion Joints in Simple Terms

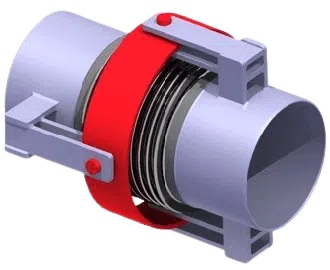

Think of a gimbal expansion joint as a controlled “hinge” inside your piping system. It allows angular movement while restricting unwanted lateral shifts. This makes it ideal for long pipelines exposed to thermal expansion, seismic activity, and pressure fluctuations—common challenges across Indian industrial zones.

According to research shared by the American Society of Mechanical Engineers (www.asme.org), unmanaged thermal expansion is among the leading causes of pipe fatigue in high-temperature systems. In simpler words: pipes naturally move, and resisting that movement usually leads to cracks.

Why Gimbal Joints Matter in Indian Industrial Projects?

From Gujarat’s petrochemical hubs to Odisha’s power plants, Indian industries operate in demanding environments. High ambient temperatures, monsoon humidity, and continuous operations create unique stresses.

- Long pipe runs: Industrial estates often require extended piping corridors.

- High thermal cycles: Frequent heating and cooling cause metal fatigue.

- Space constraints: Retrofitting flexibility is harder in crowded facilities.

Gimbal joints help absorb these stresses quietly, without disturbing nearby equipment or structures.

Best Practices for Designing with Gimbal Expansion Joints

1. Start with Accurate Movement Analysis

Before selecting any joint, calculate expected axial, angular, and thermal movements. Relying on rough estimates is risky. In my experience, even a 10% miscalculation can shorten joint life by years.

Resources like the U.S. Department of Energy (www.energy.gov) highlight how proper thermal modeling improves system efficiency and durability.

2. Choose the Right Hardware Configuration

Not all gimbal joints are created equal. Material grade, bellows thickness, and tie-rod design must match operating conditions.

- Verify pressure rating and temperature limits.

- Check corrosion resistance for local environments.

- Ensure compatibility with pipeline supports.

This is where working with an experienced

gimbal expansion joints manufacturer becomes invaluable. They understand how Indian operating conditions differ from textbook examples.

3. Design Proper Anchors and Guides

A gimbal joint is only as effective as the system around it. Without strong anchors and well-placed guides, forces will redistribute unpredictably.

A simple rule many engineers follow: “Control the movement, don’t fight it.” Anchors should absorb pressure thrust, while guides direct expansion safely.

4. Monitor Stress Signals Early

Pipelines usually warn you before failure—through vibration, noise, or misalignment. Ignoring these signs is costly.

If you are unsure what to watch for, this guide on Top Signs Your Pipe Movement System is Under Stress offers practical insights from field experience.

Common Mistakes Engineers Still Make

Despite better tools and software, some errors continue to appear on project sites:

- Oversizing joints “just to be safe”

- Ignoring cyclic fatigue analysis

- Using generic supports instead of engineered guides

Ironically, these shortcuts often increase maintenance costs rather than reducing them.

Additional Design Factors to Consider

Beyond basic calculations, modern piping design also focuses on:

- Thermal expansion management for high-efficiency plants

- Industrial piping flexibility in compact layouts

- High-temperature pipeline systems for energy-intensive processes

Balancing these elements leads to systems that remain reliable for decades.

Frequently Asked Questions (FAQs)

Q1: Are gimbal expansion joints suitable for all industries?

They are ideal for power, chemical, oil & gas, and heavy manufacturing. However, selection depends on pressure, temperature, and movement requirements.

Q2: How long do gimbal expansion joints usually last?

With proper design and maintenance, they can perform reliably for 15–25 years, depending on operating cycles.

Q3: Do these joints require frequent maintenance?

Not usually. Periodic visual inspection and alignment checks are sufficient in most installations.

Q4: Can existing pipelines be retrofitted with gimbal joints?

Yes, but structural evaluation and stress analysis are essential before retrofitting.

Final Thoughts

Designing piping systems with gimbal expansion joints is both an engineering discipline and a practical art. In India’s fast-growing industrial landscape, flexibility is no longer optional—it is strategic. When movement is managed intelligently, systems last longer, operate safer, and deliver better returns on investment.

Full Audio: Listen Here